Alternate title: What can be done with a 189.99 USD (MSRP) 3D Printer?

Thought I might share this experiment using a 3D printer with a 100 micron resolution and a print volume of a 4.7 inch cube.

Originally I was going to use my plans to cut styrene sheets (corrugated and smooth) and create the 15 foot diameter by 54 foot tall grain silo in O scale.

However, after prototyping a throttle, I decide to test the capabilities of the 3D printer.

The Experimental Portion

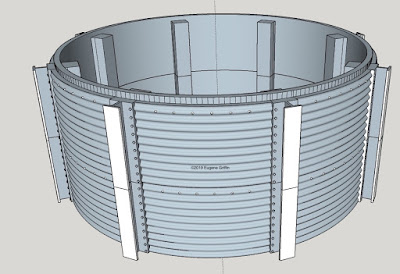

For the experiment a 15 scale foot diameter by 40 scale inch high portion of the grain silo was created in SketchUp Make.

The corrugated siding has ribs 4 inches on center with heights (depths) of 1 inch. The rivets are 1 inch diameter with a head 1/2 inch in height. The H-beams have a 1 foot dimension (it is an experiment and 1 foot H-beams are a little big).

Two 40 scale inch portions will be stacked for the print.

The STL file is exported from SketchUp Make and imported into Ultimaker Cura. The function of the Ultimaker Cura program is to produce gcode that is used to control this 3D printer.

Prior to printing the above, a section of a larger diameter silo was printed at the layer height of 0.13125 mm (the same as the throttle body).

At this resolution the corrugated ribs have definite striations created by the layering of the PLA. These might be covered by painting or possible use of a heat gun to smooth the PLA.

The print layer height was increased to 0.0875 mm for the next test print.

The corrugated ribs are definitely smoother, however the H-beams have visible lines. Most of the rivets printed, holes in the the rib in the center of the above photo are missing rivets.

Overall not bad for the first test.

I miscounted the number of supporting columns on the prototype silo, there should have been 10 not 8.

The printers 100 micron resolution (0.1 mm) should mean 1/2 inch objects are approaching the minimum size for printing.

For this printing a 0.0875 mm print layer height was used and the print took 8 hours and 7 minutes.

This section is 40 scale inches in height and has a 30 scale inch hatch. The 1 inch diameter rivets are visible and are close to the correct scale size. The hatch was printed a little smaller than expected.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.